Process Manufacturing

Any industry that produces bulk quantities of goods, including pharmaceuticals, food, chemicals, or cosmetics is seeking to improve product quality and get their products to market quicker. Simulation is increasingly used by engineers and scientists during research, development, and through to process improvement to achieve these goals. The use of computer-aided engineering (CAE) tools reduces development time and dependence on costly physical prototyping and testing.

Increase Process Efficiency

The use of computer simulation in the process manufacturing industries can help improve understanding of processes and provide key insight into operations otherwise difficult or sometimes impossible to obtain. This can result in increased process efficiency and help drive product and process innovation.

Improve Product Quality

Numerical simulation provides the means to control product consistency and quality. It can help companies develop new process strategies and evaluate the effects of process design and scale up on product characteristics. It is a powerful predictive tool that can support the adoption of continuous manufacturing.

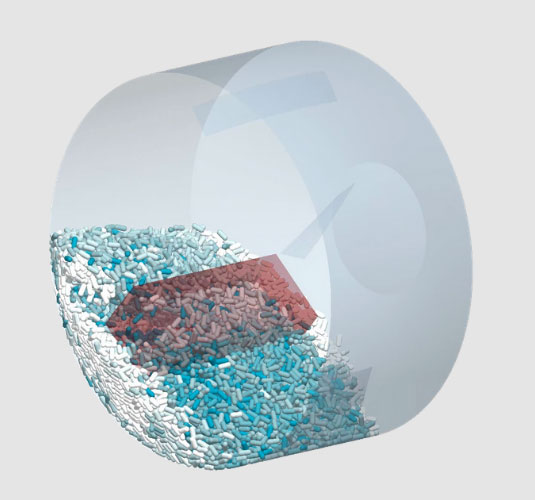

Mixing

Altair® EDEM™ can simulate the mixing process of powders, tablets, aggregates, and other granular materials. It provides fundamental information such as the particle velocities and trajectories and allows for the prediction of mixing and segregation rates as well as the identification of dead zones. This enables operators to make informed decisions on the optimal process operational parameters for their equipment regarding the impact of speed, fill level, tilt angle, etc., and to assess mixing efficiency.

Tablet Coating

Coating uniformity is of critical importance for the tablet-coating process. With EDEM it is possible to obtain key parameters such as the residence time of the tablets under the coating spray, intra-tablet coating variability, and tablets velocities pattern – many of these are difficult or even impossible to get by experimentation. EDEM can also be used to investigate how the shape of a tablet, the drum’s speed, and the fill level are influencing the coating process.

Die Filling

Die filling plays a crucial role in industries such as pharmaceuticals and powder metallurgy, where uniform processes directly influence final product quality. EDEM allows a thorough evaluation of essential parameters, providing insights into particle dynamics within the feed frame and uncovering potential segregation during die filling. This capability empowers precise process optimization, contributing to improved product quality and overall operational efficiency.

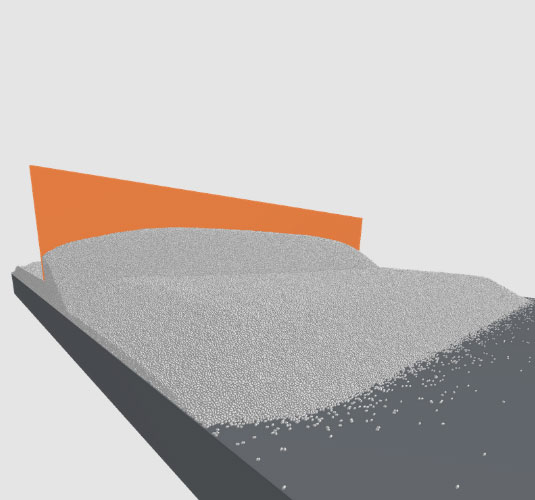

Powder Spreading and Raking

The powder spreading process in additive manufacturing (AM) has a major impact on the characteristics and quality of the final product. EDEM can be used to simulate that process and investigate the impact of different operational parameters such as roller speed on the quality of the powder bed as well as evaluating powder spreading uniformity. EDEM can be applied to various aspects of the AM process including powder delivery, spreading, and cleaning operations.

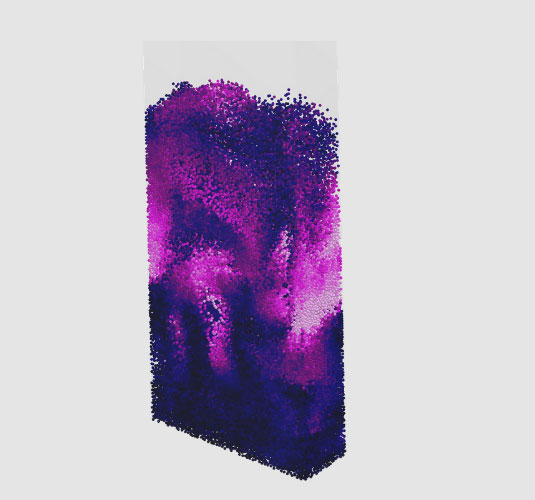

Fluidized Beds

Fluidized beds play a crucial role in industrial processes, notably in chemical processing, encompassing tasks such as freezing, cooling, heating, and coating. By integrating computational fluid dynamics (CFD) with discrete element modeling (DEM) through tools like Altair CFD™ with EDEM, companies can precisely simulate fluidized beds and particle-fluid systems, gaining valuable insights into fluidization quality, mixing, and segregation phenomena.

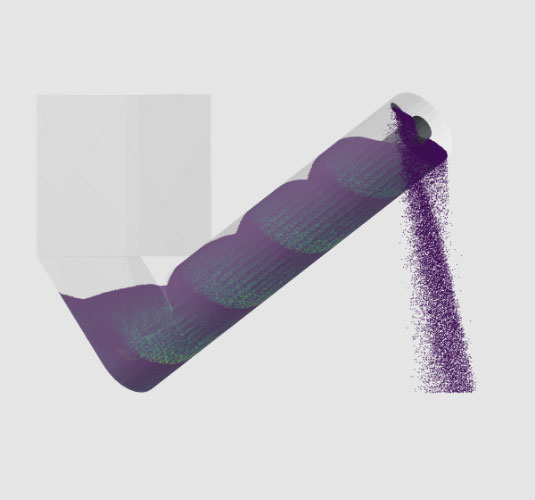

Conveying Equipment

In various industries, screw conveyors serve as a common method for transporting granular materials. Utilizing EDEM, companies gain insights into material flow rates, equipment forces, and wear. Additionally, EDEM predicts potential blockages, evaluates material mixing and compression, and provides data on system capacity and power needs. This comprehensive analysis enhances operational efficiency and facilitates informed decision-making in screw conveyor applications across industries.

Featured Resources

Guide to Process Manufacturing

Within additive manufacturing (AM), the powder spreading process significantly influences the final product's characteristics and quality. EDEM's simulation capabilities empower manufacturers to meticulously explore operational parameters like roller speed, assessing their impact on powder bed quality and uniform distribution. EDEM's versatility spans across powder delivery, spreading, and cleaning operations in different stages of the AM process.in-depth analysis yields crucial insights for optimizing the additive manufacturing workflow, ultimately enhancing efficiency and ensuring superior end-product quality.

Virtual Panel

Don't miss our upcoming virtual panel, where industry experts delve into leveraging the Discrete Element Method (DEM) for pharmaceutical manufacturing. Explore critical topics like powder system dynamics, DEM applications (mixing, coating, die filling), regulatory landscapes, and DEM's pivotal role in accelerating drug development. Featuring esteemed speakers: Dr. Fernando Muzzio (Rutgers), Dr. Liang Li (Janssen), Dr. Nima Yazdanpanah (Procegence), and Dr. Maitraye Sen (Eli Lilly). Seize this opportunity to gather valuable perspectives. Ensure your participation in this enlightening session by securing your spot now.

Flow: DEM Meets CFD

Experimentation with multiphase flow systems is crucial yet often impractical due to time, cost, and complexity constraints. Conducting experiments at micro and meso scales is particularly challenging, leading to early-stage failures in industrial processes. Fortunately, advancements in computational tools like Computational Fluid Dynamics coupled with Discrete Element Method (CFD-DEM) offer viable solutions. This approach finds applications across diverse fields including chemical, food, pharmaceutical, and mechanical engineering, facilitating in-depth analysis and problem-solving for solids-related challenges.