Simulation Design for Manufacturing

Altair offers a unique set of simulation tools to evaluate product feasibility, optimize the manufacturing process, and run virtual try-outs for many traditional, subtractive, and additive manufacturing processes. Users can validate designs early in the manufacturing process with the simplicity and affordability of the simulation software, as well as use optimization technology with specific manufacturing constraints to design better, more efficient products.

Altair’s applications for product manufacturability covers applications in several industries, including automotive, aerospace, electronics, pharmaceutical, and heavy industry.

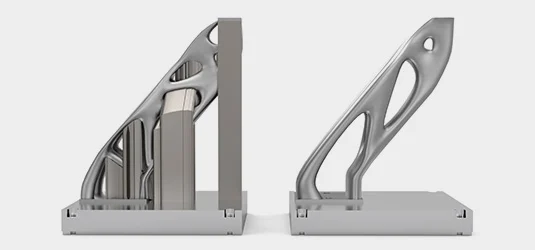

3D Printing

Altair® Inspire™ Print3D enables teams to cut product development and additive manufacturing costs by reducing material usage, print times, and post-processing. It provides a fast and accurate toolset for the design and process simulation of selective laser melting (SLM) parts. By capturing behavior independent of the printer type, designers can evaluate and easily modify critical process variables. Further manufacturing process analyses can be performed leveraging third-party tools available through the Altair Partner Alliance (APA).

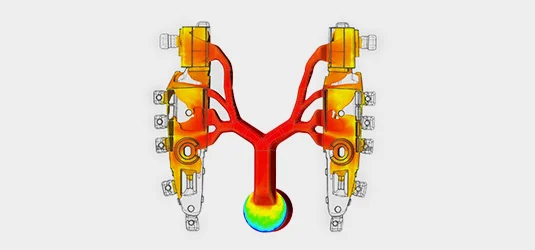

Casting

Altair’s offering includes a fast casting process simulation software that allows the user to enhance and optimize their manufactured components in order to avoid typical casting defects. Altair® Inspire™ Cast is a simulation environment focused on creating high-quality components with increased profitability through a highly intuitive user experience catering to beginners and experts alike. Additional casting simulations products are accessible through the APA.

Injection Molding

Altair® Inspire™ Mold is a modern, integrated software to streamline design for manufacturing (DfM) of injection molded components. Fast, accurate simulations answer the question “will it fill?” for even large, complex parts in under an hour. Identify potential manufacturing defects early in the development process and make better, more informed design decisions. Leap from manufacturing “know how” to “know why,” deliver superior products, reduce scrap, and slash tooling rework costs. For more advanced analysation we offers a seamless, simulation

Metal Forming

Altair® Inspire™ Form is a sheet metal forming simulation software that enables users to optimize their products for manufacturing, with the consideration of early formability, material utilization, and cost. Cold and hot sheet metal forming, tube bending, hydroforming, and composite forming are supported. Run early manufacturing feasibility analysis within seconds or perform advanced process validation, optimization, and virtual try-outs leveraging an accurate, highly-scalable solution.

Extrusion

Every extrusion company is looking to eliminate costly prototypes and reduce redesign cycles. With Altair, advanced physics simulations are now accessible to organizations of all sizes. Altair® Inspire™ Extrude is a simulation solution for both metal and polymer extrusion. It helps achieve productivity gains by reducing product development costs and improving extrusion quality, increasing production yield. Lower scrap rates can be achieved by exploring process improvements on a virtual press.

Process Manufacturing

or sometimes impossible to measure.

Polyurethane Foaming

Rigid and flexible polyurethane foams, also known as cellular or expanded polymers, surround us. Their important attributes like lightweight, adaptable strength per unit weight, and insulation characteristics, as well as their inherently high sustainability make them attractive for an increasingly wide range of industrial and household applications. Altair® Inspire™ PolyFoam provides a modern integrated approach to streamline DfM of flexible molded foam components.

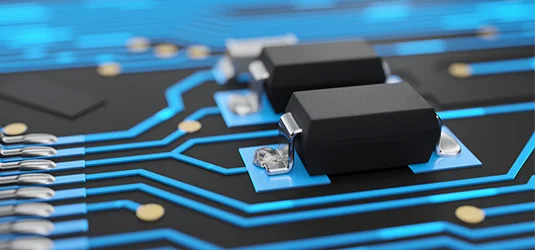

Circuit Boards and Electronics

and tightly packaged electronic products.

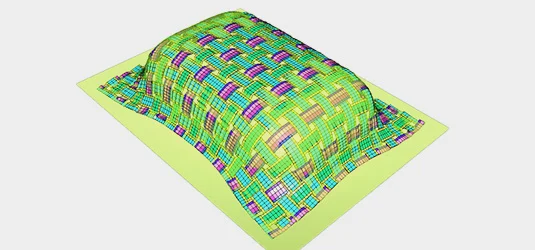

Composites

Composite material behavior is defined as components are manufactured. Develop and simulate multiscale heterogeneous material models with Altair® Multiscale Designer™, while assuring manufacturability with draping and forming simulation for sandwich and multilayered laminates combining Altair and APA third-party products. For engineered plastics, SimLab includes a very accurate simulation of fiber orientation during filling and analysis of the structural performance of the complete assembly.